What if the way we build today becomes obsolete tomorrow? Imagine stepping into cities where buildings rise faster, stand stronger, and harmonize seamlessly with the environment. It’s not a sci-fi fantasy but the reality we are marching toward in 2025. The construction industry is undergoing a seismic shift, driven by groundbreaking technologies and innovative techniques. This evolution is not only redefining how we build but also reshaping how we live, work, and interact with our surroundings.

Whether you are a homeowner, contractor, architect, or just someone curious about the future, this guide unpacks the revolutionary building techniques poised to transform construction forever.

Smart Materials: The Building Blocks of Tomorrow

What Are Smart Materials?

Smart materials, often referred to as “intelligent” or “adaptive” materials, can respond dynamically to environmental changes. Imagine concrete that repairs its own cracks, glass that adjusts its transparency based on sunlight, and paint that repels dirt.

Key Innovations

- Self-Healing Concrete: Developed with bacteria or capsules filled with adhesive agents, self-healing concrete automatically seals cracks when exposed to water or air, significantly extending the life of structures.

- Energy-Efficient Glass: Known as electrochromic or thermochromic glass, this innovation adapts to light and heat levels, reducing the need for artificial lighting and cooling systems.

- Shape-Memory Alloys: Used in infrastructure, these alloys return to their original shape when deformed, enhancing structural integrity in the event of natural disasters.

Real-World Impact

In 2023, a bridge in the Netherlands incorporated self-healing concrete, reducing maintenance costs by over 40%. Similarly, smart glass has been adopted in skyscrapers across Dubai, cutting energy bills by up to 30%.

Why It Matters

By reducing long-term maintenance costs and enhancing durability, smart materials address two critical challenges: sustainability and affordability. As these materials become mainstream, expect smarter homes and cities with lower environmental footprints.

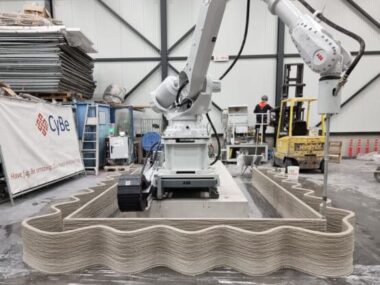

3D Printing: From Imagination to Reality in Hours

The Revolution of Layer-by-Layer Construction

3D printing, or additive manufacturing, involves creating structures layer by layer using specialized machines. It’s no longer limited to small prototypes—it’s building entire homes and commercial spaces.

Advantages

- Speed: Traditional construction timelines of months are condensed into days.

- Precision: Designs are executed with millimeter-level accuracy, reducing errors.

- Sustainability: Many 3D printers use recycled or bio-based materials, lowering waste.

Comparative Insight

While traditional brick-and-mortar construction involves manual labor and logistical challenges, 3D printing eliminates many inefficiencies. For example, a 400-square-foot home printed in Texas took just 24 hours, compared to a month-long traditional timeline.

Applications Beyond Housing

- Emergency Shelters: NGOs are using 3D printing to construct shelters in disaster-hit regions.

- Bridges and Infrastructure: China recently unveiled a 3D-printed pedestrian bridge made entirely of recycled materials.

- Luxury Designs: Architects are exploring 3D printing for intricate, custom designs previously impossible with conventional methods.

Modular Construction: Building Smarter, Faster, and Safer

What Is Modular Construction?

Think of modular construction as assembling a puzzle where the pieces are pre-built off-site. Entire rooms or sections are manufactured in controlled environments and then transported to the site for assembly.

Benefits

- Speed: Construction time is cut by 30% to 50%.

- Consistency: Controlled manufacturing ensures uniform quality.

- Eco-Friendly: Off-site fabrication reduces on-site waste by up to 90%.

Case Studies

- Residential Housing: In Singapore, modular techniques have slashed housing development timelines by half.

- Healthcare Facilities: During the COVID-19 pandemic, modular construction was pivotal in creating temporary hospitals in record time.

- Commercial Spaces: Marriott has embraced modular construction for hotels, opening properties in weeks instead of months.

Future Potential

With urbanization accelerating, modular construction offers a scalable solution to housing shortages. By 2030, experts predict modular methods could account for over 20% of global construction.

AI and Robotics: The Brain and Brawn of Modern Construction

Artificial Intelligence: The Mastermind

AI algorithms are revolutionizing project planning and execution:

- Predictive Analytics: AI can forecast delays, optimize budgets, and manage resources effectively.

- Design Optimization: Tools like generative design create cost-efficient and structurally sound building plans.

- Risk Mitigation: AI detects potential hazards, ensuring safer construction sites.

Robotics: The Workforce of the Future

Robots are taking over repetitive, dangerous tasks, including:

- Bricklaying: Machines like SAM (Semi-Automated Mason) lay bricks six times faster than humans.

- Excavation: Robotic excavators streamline digging processes with precision.

- Demolition: Remote-controlled robots safely dismantle structures in hazardous environments.

Real-World Testimonials

A construction firm in Japan reduced project costs by 15% using AI for resource allocation and robots for material handling. Workers reported improved safety and job satisfaction as robots handled hazardous tasks.

Green Construction: Building with Nature in Mind

Why Green Construction Matters

As climate change intensifies, the construction industry is under pressure to adopt sustainable practices. Green construction techniques emphasize renewable resources, energy efficiency, and eco-friendly designs.

Innovations Driving Change

- Net-Zero Buildings: Structures that produce as much energy as they consume are becoming the gold standard.

- Vertical Gardens: High-rises with green facades improve air quality and reduce urban heat.

- Renewable Materials: Bamboo, mycelium, and recycled steel are replacing traditional materials.

Inspiring Projects

- The Bosco Verticale: This Milan skyscraper features over 900 trees, reducing carbon emissions while beautifying the skyline.

- The Edge (Amsterdam): A smart, net-zero office building that uses solar panels, rainwater harvesting, and AI-driven energy management.

Digital Twins: Simulating Perfection Before Breaking Ground

What Are Digital Twins?

A digital twin is a virtual replica of a building or infrastructure project. It allows architects and engineers to simulate real-world performance, from structural integrity to energy consumption.

Advantages

- Cost Savings: Early detection of design flaws reduces rework.

- Enhanced Collaboration: Teams can visualize and refine designs in real-time.

- Sustainability: Simulations optimize resource usage and minimize waste.

Use Case

Before constructing a $1 billion airport terminal, developers in Qatar used digital twins to test designs, saving millions by avoiding structural inefficiencies.

Augmented Reality (AR): Redefining Design and Collaboration

How AR Works

AR overlays digital information onto the real world. For construction, this means visualizing a building’s layout, materials, and finishes before breaking ground.

Key Applications

- Design Visualization: Walk through virtual rooms and adjust layouts on the fly.

- Training: AR-based simulations train workers in real-world scenarios without risks.

- Site Management: Supervisors use AR to monitor progress and identify issues.

Testimonial

An architect in Los Angeles reported a 25% reduction in client revisions after implementing AR for project presentations, as clients could visualize end results more clearly.

FAQs: What You Need to Know About the Future of Construction

1. Are these technologies expensive?

While initial costs may be high, the long-term savings in maintenance, labor, and energy make them cost-effective.

2. How do these techniques impact jobs?

Rather than eliminating jobs, these innovations are shifting roles. Workers are transitioning from manual labor to tech-savvy roles like operating robots or managing digital systems.

3. When will these technologies become mainstream?

Many are already in use globally. By 2030, they are expected to dominate new construction projects.

Embrace the Future of Construction

The construction techniques of 2025 are more than innovations—they are necessities for a growing, urbanized world. From smart materials and 3D printing to AI and green construction, these advancements are reshaping every facet of the industry.

Whether you’re an industry leader or a future homeowner, embracing these changes today ensures you remain ahead in tomorrow’s world. For more in-depth insights, resources, and expert guidance, explore our dedicated hub and join the movement shaping the future of architecture.