Have you ever wondered why some construction companies thrive in uncertain times while others struggle to stay afloat? What if the secret to surviving—and thriving—in the construction industry lies in adopting cutting-edge cost-saving innovations?

The construction world evolves rapidly, driven by rising material costs, labor shortages, and growing environmental concerns. Companies must innovate to remain competitive. In this article, we will explore groundbreaking advancements shaping the industry. These innovations will not only help you save money but also boost efficiency and give your company a competitive edge.

Shifting From Traditional to Smart Construction

The Decline of Traditional Methods

Traditional construction methods dominated the industry for decades. However, their inefficiencies, high costs, and susceptibility to errors are no longer sustainable in today’s fast-paced market. The industry demands smarter, more efficient approaches.

Embracing Smart Technologies

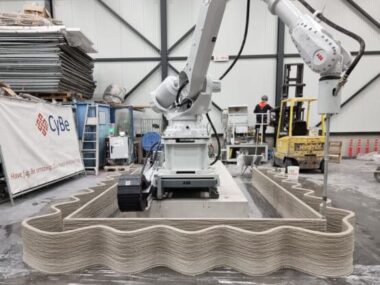

Smart construction technologies, including 3D printing, robotics, and AI-driven processes, are revolutionizing the field. These innovations drastically reduce costs while improving precision and productivity.

- 3D Printing: This technology eliminates the need for expensive molds, reducing material waste by up to 90%. For instance, a construction firm in the Netherlands used 3D printing to create a fully functional bridge, saving weeks of labor and significant costs.

- Robotics: Robotics automate repetitive tasks like bricklaying and welding. By delegating these tasks to machines, companies free up workers for higher-value activities, improving overall productivity.

- AI-Powered Planning: AI algorithms analyze project data to optimize schedules, forecast potential delays, and enhance resource allocation.

Real-World Testimonial:

“By integrating robotics into our workflow, we cut labor costs by 25% and completed projects 30% faster. It’s a win-win,” says Mark Jensen, CEO of BuildSmart Solutions.

Green Building Materials: Saving Costs While Saving the Planet

A Greener Approach to Construction

Sustainable building materials are transforming the industry. Contractors are now choosing eco-friendly options like recycled steel, engineered wood, and low-carbon concrete. These materials are not only environmentally friendly but also cost-effective.

The Case for Low-Carbon Concrete

Low-carbon concrete uses less energy during production and emits fewer greenhouse gases. It’s also more durable than traditional concrete, which translates to reduced maintenance costs over time.

Comparison:

| Traditional Concrete | Low-Carbon Concrete |

|---|---|

| High energy usage | 40% less energy used |

| Shorter lifespan | More durable |

| Higher maintenance | Lower costs |

Example:

In Singapore, a construction firm adopted low-carbon concrete for a high-rise project. This decision reduced project costs by 18% and earned the company recognition for sustainability.

Transition Tip: Start small with sustainable materials to test their cost-effectiveness before scaling up.

The Digital Revolution in Construction Management

The Shift to Digital Tools

Why stick with manual processes when digital tools can revolutionize project management? Today, cloud-based software like Procore, Buildertrend, and Autodesk Construction Cloud offers unparalleled precision.

How Software Drives Savings

- Automated Workflows: Software reduces human errors, cutting rework costs by up to 50%.

- Cost Forecasting: Digital platforms analyze trends to predict expenses, helping companies stay on budget.

- Collaboration Tools: Teams can communicate in real time, reducing delays caused by miscommunication.

Real-World Example:

A medium-sized contractor in Texas reported saving $200,000 annually after switching to Procore, citing fewer delays and improved coordination.

FAQs About Construction Management Software

- Is the investment worth it for small businesses?

Yes. Many platforms offer scalable solutions that grow with your business. - How steep is the learning curve?

Most software providers offer training and support to ensure seamless integration.

Prefab and Modular Construction: Building Smarter, Not Harder

What Are Prefab and Modular Construction?

Prefabrication involves manufacturing building components in a controlled environment, while modular construction assembles entire sections offsite. These methods significantly reduce time and costs.

Benefits of Modular Construction

- Time Savings: Offsite construction eliminates weather delays, reducing project timelines by up to 50%.

- Cost Reduction: Bulk material orders and reduced labor expenses lead to significant savings.

- Sustainability: Prefab methods generate less waste, aligning with green building goals.

Case Study:

A school district in California used modular construction to build classrooms in half the expected time, saving $2 million in labor costs.

Energy-Efficient Systems: An Investment That Pays Off

Why Energy Efficiency Matters

Energy-efficient systems lower operating costs and contribute to long-term savings. Technologies like smart HVAC systems, solar panels, and LED lighting are gaining popularity.

Real Savings, Real Impact

- HVAC Systems: Modern HVAC systems use sensors to optimize energy use, reducing utility bills by 20–30%.

- Solar Panels: Though the upfront cost is high, tax incentives and lower energy bills make them a wise investment.

- Smart Lighting: Motion-activated lights reduce electricity usage, slashing costs by up to 40%.

Testimonial:

“Switching to energy-efficient HVAC systems saved our company $50,000 annually. It’s the best decision we’ve made,” says Sarah Lopez, a project manager.

Autonomous Machinery: The Future of Jobsite Efficiency

The Rise of Autonomous Machinery

Autonomous equipment like self-driving excavators, drone surveys, and robotic forklifts is reshaping construction sites.

Key Advantages

- Increased Productivity: Autonomous machinery completes tasks faster than human workers.

- Enhanced Safety: Machines minimize safety risks, reducing costly accidents.

- Better Data Collection: Drones provide accurate site data, improving decision-making.

Example:

A construction company in Arizona deployed drones for site inspections. The drones completed surveys in one-third of the time, saving $100,000 annually on labor.

Real-Time Data: The Construction Industry’s New Currency

The Power of IoT Devices

Internet of Things (IoT) devices provide real-time data, transforming how projects are managed. These devices monitor equipment performance, track material usage, and detect issues early.

How IoT Reduces Costs

- Preventative Maintenance: Sensors alert teams to equipment issues before they escalate.

- Material Tracking: IoT systems monitor inventory, reducing waste.

- Improved Accuracy: Real-time updates help managers make informed decisions, avoiding costly mistakes.

Case Study:

A Canadian contractor adopted IoT technology to monitor material usage. This reduced waste by 15%, saving $500,000 annually.

Frequently Asked Questions About Cost-Saving Innovations

- Are these innovations suitable for small contractors?

Absolutely. Many technologies offer scalable solutions, making them accessible to businesses of all sizes. - What is the ROI on these investments?

Most companies see ROI within 12–24 months, depending on the technology. - How can I start integrating these innovations?

Begin with one or two technologies, such as management software or sustainable materials, to ease the transition.

Conclusion: The Future Is Here—Are You Ready?

The construction industry is undergoing a transformation. Companies that embrace cost-saving innovations will gain a competitive edge and secure their place in the market. From adopting smart technologies to utilizing sustainable materials, the opportunities are endless.

Take Action Today:

- Evaluate your current processes.

- Research technologies that align with your goals.

- Start small and scale up as you see results.

Don’t let your business fall behind. Begin exploring these innovations today and revolutionize your projects. For more insights and resources, visit [Here].